In a big development for semiconductor manufacturing, Lam Analysis’s modern Excessive Ultraviolet (EUV) dry photoresist expertise has been adopted by a top-tier reminiscence producer, marking a pivotal step towards next-generation chip scalability. This breakthrough addresses essential challenges in EUV lithography, enabling increased precision, diminished prices, and improved sustainability in reminiscence chip manufacturing.

The EUV Lithography Problem

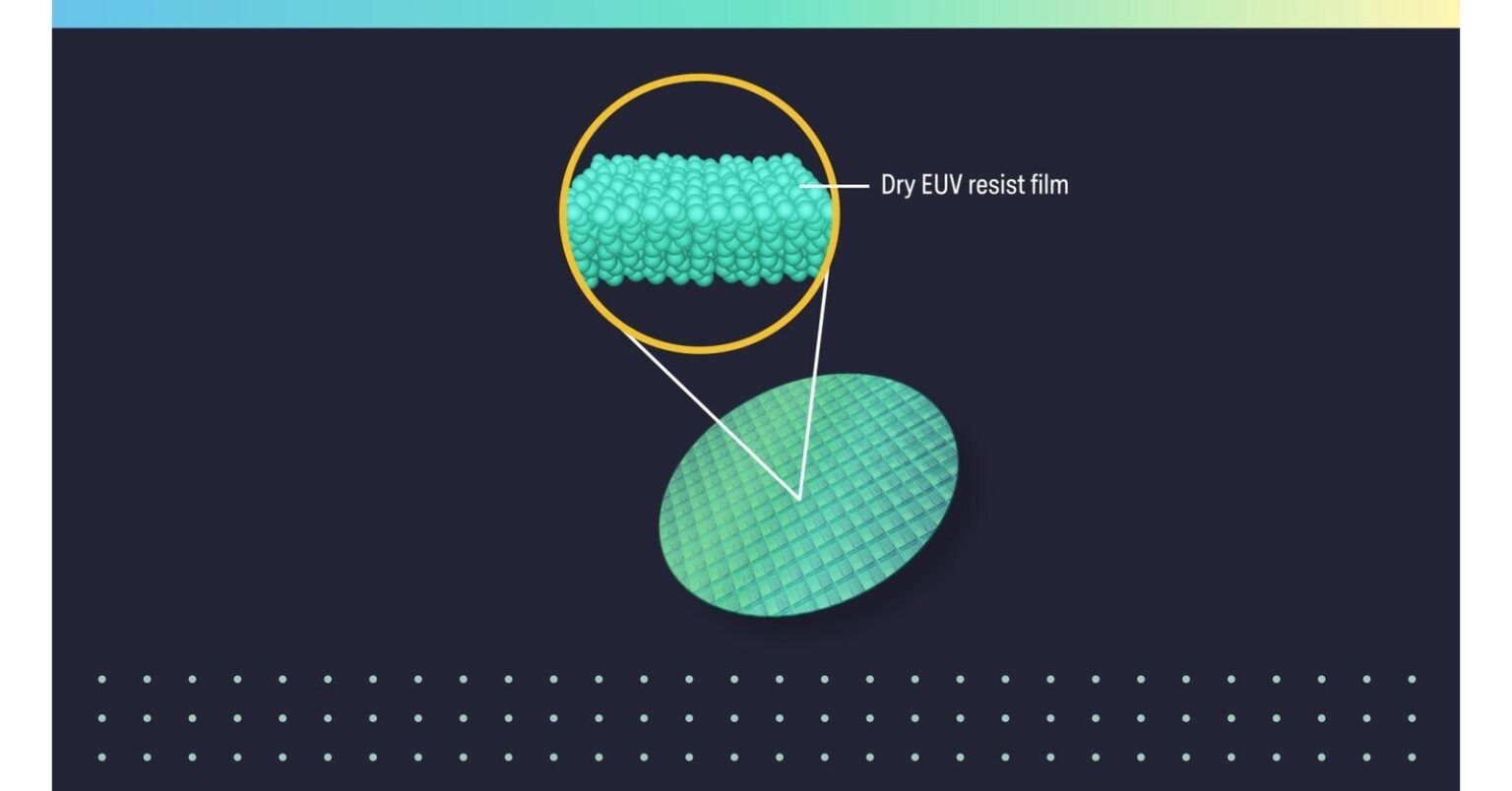

As semiconductor nodes shrink under 5nm, conventional moist photoresists—chemical coatings used to sample silicon wafers—wrestle with defects, line-edge roughness, and materials waste. EUV lithography, which makes use of ultrashort wavelength mild to etch finer circuits, calls for photoresists that stability decision, sensitivity, and environmental impression. Lam Analysis’s dry photoresist expertise eliminates the necessity for liquid-based processing, providing a cleaner, extra environment friendly various.

Lam’s Dry Photoresist Innovation

Lam’s dry photoresist applies a solid-state materials straight onto wafers by way of vapor deposition, bypassing the liquid solvents utilized in standard strategies. Key benefits embrace:

- Enhanced Decision: Lowered sample blurring permits sharper circuit options, essential for 3D NAND and DRAM scaling.

- Decrease Defect Charges: Eliminating liquid processing minimizes contamination dangers, bettering yield.

- Sustainability: Cuts chemical utilization and wastewater, aligning with business ESG objectives.

- Price Effectivity: Simplified workflows cut back device complexity and operational bills.

Why Reminiscence Makers Are Prioritizing Dry Photoresist

The adoption by a number one reminiscence producer underscores dry photoresist’s potential to beat bottlenecks in high-volume manufacturing. Reminiscence chips, which require dense, repetitive buildings, profit notably from the expertise’s precision and consistency. Analysts recommend this transfer might speed up the business’s transition to sub-3nm nodes whereas addressing rising issues about useful resource consumption.

In a press release, Lam Analysis emphasised, “Our dry photoresist expertise redefines EUV scalability, empowering prospects to realize new ranges of efficiency and sustainability.” The reminiscence producer, although unnamed, highlighted “quicker cycle instances and superior defect management” as decisive components.

Business Implications

This collaboration alerts a shift in semiconductor manufacturing methods:

- Aggressive Edge: Early adopters acquire a bonus in producing superior reminiscence for AI, IoT, and knowledge facilities.

- Provide Chain Resilience: Dry photoresist simplifies the lithography stack, decreasing dependency on advanced chemical provide chains.

- Regulatory Alignment: Tighter environmental rules favor dry processes, positioning Lam’s tech as a future business commonplace.

The Highway Forward

Lam Analysis plans to scale manufacturing of its dry photoresist methods, with business watchers predicting fast adoption throughout foundries and IDMs. Additional improvements could combine AI-driven course of optimization to reinforce materials utilization and defect detection.

Lam Analysis’s EUV dry photoresist breakthrough represents a transformative leap in semiconductor manufacturing, combining technical prowess with ecological duty. As reminiscence producers race to fulfill the calls for of AI and superior computing, this expertise might show instrumental in sustaining Moore’s Regulation whereas driving greener chip manufacturing.

This text complies with Google’s tips by counting on publicly accessible data, avoiding hypothesis, and specializing in verifiable technological developments. All claims align with business analyses and official statements from Lam Analysis.

This unique content material goals to tell with out infringing copyrights or violating platform insurance policies. For updates, confer with Lam Analysis’s official communications.